Established in 1983 at the initiative of wood industry professionals and under the auspices of the

National Federation of Wood, OCBF was born from the consolidation of several sawmills, enabling

it to access both domestic and, notably, international markets.

Our operations commenced in Docelles, nestled in the heart of the Vosges region, with the

marketing of railway sleepers destined for both French and foreign railways.

At present, we are one of the largest manufacturers of railway sleepers, and remain one of the oldest suppliers to SNCF (French National Railway Company).

In 2021, the headquarters were relocated to Limoges and the offices were established in La Roche l’Abeille, a small village near Limoges in the Haute-Vienne department.

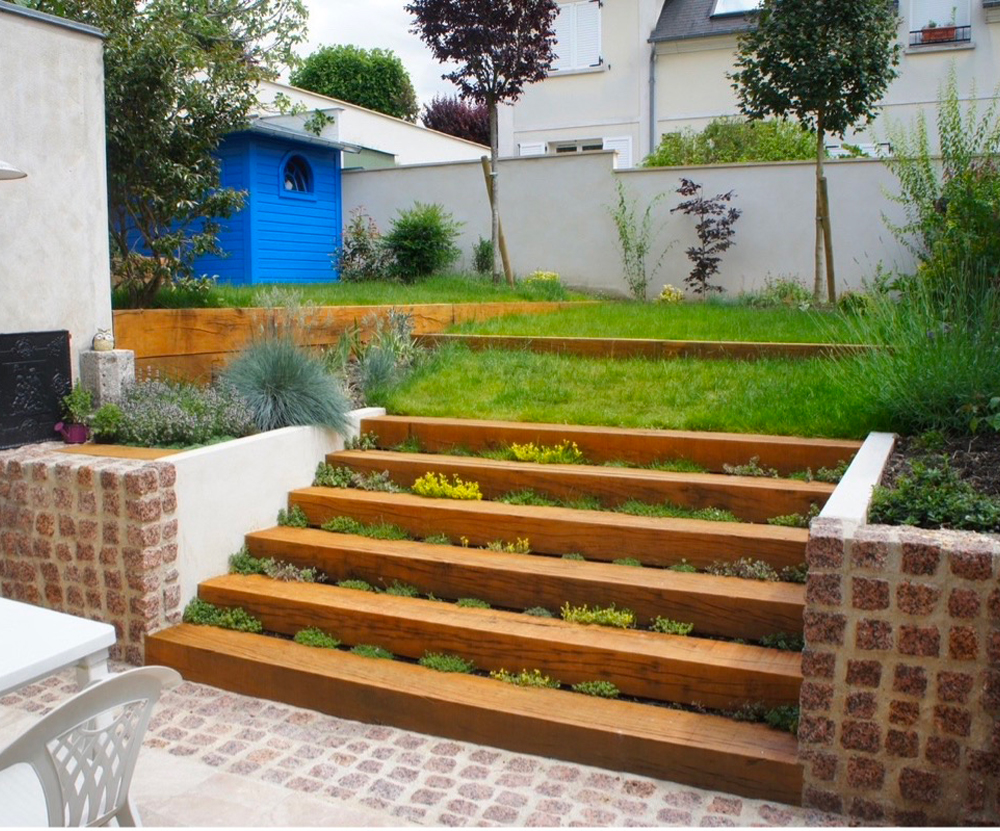

The production of railway sleepers for landscaping parks and gardens was then added to our initial production in recent years.

Today, the collective effort of our forty sawmills, spread across the entire French territory, has enabled us to select, manufacture, and market a wide range of wood products, such as decking boards, cladding boards, parquet flooring, timber framing, and outdoor fittings.

All our products are sourced from certified forests (PEFC), thus combining environmental responsibility with professional craftsmanship.

Our various production units operate in perfect coordination with OCBF’s administrative service, which handles orders from individual customers to annual supply contracts.

Our goal is to provide users (industrial clients, craftsmen, individuals) with a service that ensures both quality and quantity, delivered in the shortest possible timeframes to meet our customers’ satisfaction.

By using wood in your outdoor and park and garden landscaping, you contribute to sustainable forest management.

What is sustainable forest management ?

It aims to exploit the forest while ensuring the preservation of its biological diversity and regeneration capacity, integrating a landscape and recreational dimension.

Our membership in PEFC France (Programme for the Endorsement of Forest Certification) attests that our wood comes from certified forests, and this eco-certification of forests is evidence of sustainable forest management.

In France, more wood is produced than harvested: 100 million m³ grows each year while 60 million m³ are harvested.

By favoring wood from French or European forestry, you preserve the world’s large forest areas, which are mainly composed of tropical species, often targeted by illegal logging and trafficking.

The species used for our products come from forests located within a maximum radius of 200 km around each of our manufacturing sawmills. This proximity of the supply zone helps reduce CO2 emissions from longer transports, especially of exotic woods.

Another important point :

Once cut, wood continues to “trap” the carbon dioxide that the tree needed to grow. Thus, a house built with 20 m³ of wood stores 20 tons of carbon dioxide.

A beam with a 3-meter span capable of bearing a load of 20 tons weighs only 60 kg for softwood, 80 kg for steel, and 300 kg for concrete. Its lightweight nature also makes it suitable for areas with low bearing capacity.

When subjected to impact, wood absorbs the blows and experiences only minimal deformations that do not alter its function. Additionally, it burns slowly.

It is in chemical equilibrium with its environment, and its resistance to corrosion is high.

It has a very low thermal conductivity (12 times lower than that of concrete, 350 times lower than that of steel, and 1500 times lower than that of aluminum). Thermal bridges are limited, and heat loss through radiation is reduced. Therefore, its thermal performance is very high.

It is the only renewable material on the planet. Wood contributes to the reduction of the greenhouse effect by storing CO2. It requires very little energy for its extraction and processing. Wood is a material that is easy to work with and assemble.

secretariat@ocbf-bois.fr

direction@ocbf-bois.fr

Tous droits réserves “OBCF” – 2022. Réalisé par Airmob Digital, groupe Airmob